As a B2B operator, you already understand the fundamentals of warehousing, freight, and service-level discipline. What’s changing is the pressure on cost, speed, and flexibility: customers expect tighter lead times, cleaner data, and more customization … but you don’t want to erode your margins. When your current fulfillment setup starts missing SLAs, limiting configuration options, or driving up total landed cost, the question isn’t whether to outsource—it’s whether you have the right partner.

Choosing a new B2B fulfillment partner is less about “getting boxes out the door” and more about finding an extension of your operations team. The right provider should improve rate structures, service reliability, and the ability to support complex customer requirements—without forcing a disruptive re-architecture of your internal systems. In practice, that means evaluating their network, technology stack, and operating model against the realities of your business, not against a generic best-practice checklist.

This article focuses on how established, growing B2B companies can assess potential fulfillment partners: what a modern B2B order fulfillment solution should deliver, the questions that separate commodity 3PLs from strategic partners, and how to evaluate pricing beyond headline rates.

What B2B Fulfillment Means for a Mature Operation

For an established B2B company, a fulfillment “solution” is not simply a warehouse plus labor. It’s an integrated combination of infrastructure, technology, and process that can absorb growth, complexity, and seasonality without constant firefighting from your internal team. At its core, it should enhance your existing operating model rather than forcing you to work around its limitations.

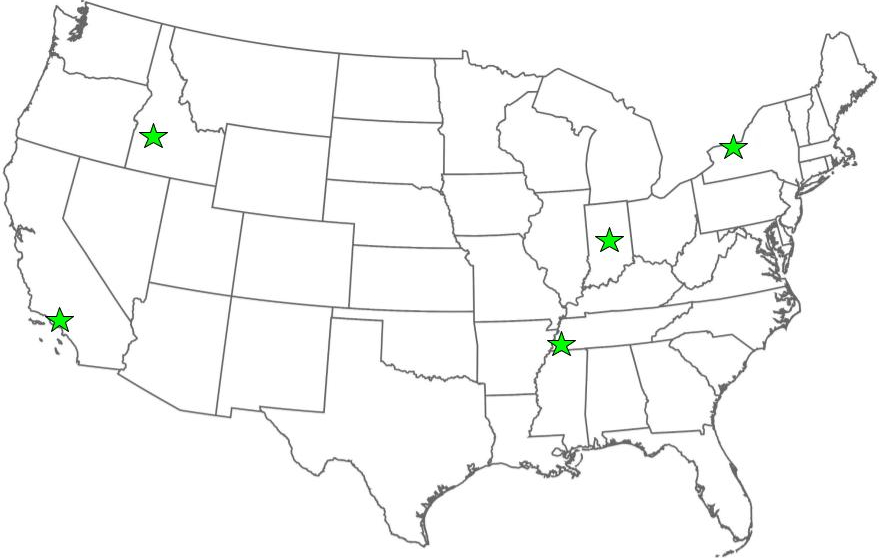

On the infrastructure side, you’re looking for footprint and capabilities that match your go-to-market strategy: the right mix of locations, material-handling equipment, and value-added services to support current and planned channels. That might include light assembly, kitting, custom packaging, or vendor-specific prep requirements—all delivered with consistent SLAs across accounts.

On the technology side, the key is depth and reliability of integration with your ERP, OMS, TMS, and e-commerce fulfillment stack. You’re not evaluating whether they “have a system,” but whether their WMS, EDI/API layer, and reporting can provide real-time visibility, clean master data, and robust exception handling without creating parallel, manual workflows for your team.

Finally, a true solution is defined by process discipline: how the partner manages inbound variability, order prioritization, carrier and mode optimization, and continuous improvement. The best B2B fulfillment services function like an extension of your operations organization, with governance, KPIs, and cadence that mirror what you expect from internal teams.

The 3 Make-or-Break Questions for Any Potential Fulfillment Partner

Once you’re speaking with potential partners, most will sound similar at a high level. To separate a transactional provider from a strategic B2B fulfillment center, focus on three make-or-break areas.

- Can the Fulfillment Partner Support Our Current and Future Complexity?

Go beyond generic capabilities and test for real-world fit. Ask how they handle value-added services such as kitting, light assembly, relabeling, and custom packaging at scale. Request concrete examples of customers with similar order profiles, line counts, and compliance requirements—and what OTIF, error rates, and change-order performance look like for those accounts. - How Well Does the Order Fulfillment Partner Integrate With Our Systems?

You’re not looking for a basic EDI connection; you’re evaluating the overall data flow between systems. Clarify which documents and events are exchanged (orders, ASNs, inventory adjustments, status updates), typical latency, and how exceptions are handled. Ask who owns mapping and maintenance when trading partners or platforms change, and how they support multi-channel order fulfillment solutions across B2B, marketplaces, and direct e-commerce without creating data silos. - How Does the Fulfillment Partner Handle Customer-Specific Requirements?

Established B2B brands already live with complex routing guides, labeling rules, and chargeback regimes. Ask prospective partners how they operationalize retailer and distributor requirements, how frequently they update their rule sets, and what governance they use to prevent penalties. Look for evidence that compliance is embedded into their processes and systems—not managed via tribal knowledge on the warehouse floor.

B2B Fulfillment Pricing: How to Evaluate Total Cost, Not Just Rates

For a mature operation, the question is not simply “Is this partner cheaper?” but “How will this pricing model behave under our real volumes, seasonality, and service mix?” Most B2B fulfillment services will quote a familiar structure—receiving, storage, pick/pack, and shipping-related fees—but the details determine whether your cost profile is predictable or volatile.

Start by modeling a few representative scenarios: a typical weekly order mix, a peak period, and a large new-account onboarding with higher value-added services. Ask for line-item pricing against each scenario, including surcharges and accessorials. This will expose whether their rate card rewards the way you actually operate or penalizes you for order complexity, multi-line shipments, or frequent configuration changes.

Next, look at how freight costs are handled. Clarify whether they pass through carrier rates, apply markup, or leverage their own contracts to improve your landed cost. For many B2B operators, the biggest savings opportunity is not in a slightly lower pick fee but in better carrier mix, mode selection, and carton/pallet optimization across all channels, including e-commerce fulfillment where applicable.

Finally, evaluate transparency and controllability. You should be able to track cost per order, per customer, and per channel through their reporting—ideally integrated into your own dashboards. A partner that can’t provide clear, timely data will make it difficult to manage profitability or identify where changes in process could materially improve cost and service.

When B2B Fulfillment Becomes a Strategic Advantage

Fulfillment should not be the bottleneck that limits your ability to say “yes” to new customers, channels, or configurations. The right B2B order fulfillment solution gives you confidence that operations can scale with the commercial plan—supporting larger contracts, tighter SLAs, and more complex requirements without constant executive intervention.

As a next step, build a simple, quantitative scorecard for your current and prospective partners that covers service performance, flexibility, integration quality, and total cost. Use it to run an apples-to-apples comparison based on your actual order and account mix, not on generic benchmarks. When you can see—in numbers—who will truly improve rates, service, and flexibility, the decision about your next B2B fulfillment partner becomes much clearer.