Navigating the Journey: When to Shift from In-house to Outsourced Fulfillment

If your business has progressed beyond the initial stages or a small industrial space, it is likely that you have had to make significant decisions regarding your order fulfillment process. Currently, you may be handling fulfillment internally, ensuring that your products are delivered to your customers promptly and accurately. While this approach may have been effective when your business was smaller, as your business expands, relying solely on in-house resources can put a strain on your operations. This strain can potentially impact customer satisfaction and hinder the growth potential of your brand. Therefore, it is prudent to consider partnering with a national-level fulfillment company like Wolff/SMG Fulfillment.

Wolff/SMG Fulfillment specializes in e-commerce and B2B fulfillment, with a strong emphasis on optimizing omnichannel fulfillment. By collaborating with Wolff/SMG, you gain a dependable partner that can also handle inventory storage and management. This allows you to allocate your time and resources towards business growth and maintaining strong customer relationships.

Now, let’s explore some indicators that suggest it is time to transition from in-house fulfillment to outsourced fulfillment.

GROWING ORDER VOLUMES

Business growth results in an increase in the number of orders. Although this is a positive development, it can also pose a challenge for businesses that handle fulfillment in-house. As order volumes grow, the storage capacity, workforce, and logistics decisions needed to manage and ship these orders become more complex. This complexity can lead to delays in order fulfillment, errors in packing, and mistakes in shipping details, all of which can have a significant impact on customer satisfaction and retention.

Delivery speed has become the most sought-after aspect of the shopping experience for many customers. By outsourcing their order fulfillment, businesses can access scalable resources specifically designed to handle growing order volumes. Third-party logistics providers (3PLs) are equipped with the necessary workforce, systems, and infrastructure to ensure that each order is fulfilled accurately and on time, regardless of the volume.

SEASONAL PEAKS

Many businesses experience fluctuations in demand throughout the year. These could be due to specific events, such as holiday shopping for retailers, the need for summer or winter essentials, or the demand for back-to-school products. These peaks in demand often create challenges for businesses in terms of fulfilling orders and managing their supply chains. According to a survey conducted by Digital Commerce 360, online holiday shopping alone witnessed a significant growth of 45.2% in 2020. While it is possible to hire temporary staff to handle these peak periods, training them can be time-consuming and resource-intensive.

On the other hand, outsourcing fulfillment to experienced partners can provide a seamless solution to manage these seasonal changes. These partners have the capability to scale up their resources during peak times, ensuring that your customers receive their orders promptly, even during the busiest seasons. Their expertise and adaptability in handling such fluctuations make them a reliable choice for businesses during high-pressure periods.

INVENTORY MANAGEMENT ISSUES

Effective management of inventory is essential for a successful fulfillment process. Insufficient stock levels can lead to missed sales opportunities, while excessive stock can result in obsolete inventory and unnecessary storage expenses. Achieving the right balance is crucial.

As your product line grows or order volumes increase, managing inventory in-house can become increasingly complex. However, leading third-party logistics providers (3PLs) utilize advanced inventory management systems to track your stock levels in real-time. These systems can identify sales patterns and trends, forecast future stock needs, and handle reordering processes.

Furthermore, 3PLs have optimized storage systems that ensure the security and organization of your inventory. This enables efficient order picking and packing. By outsourcing inventory management to experts, you can avoid overstocking or stockouts and ensure that your orders are always prepared and ready to be shipped.

SHIPPING COSTS AND DELIVERY TIMES

Many customers are deterred by high shipping costs. According to a recent survey by the National Retail Federation, 75% of consumers now expect free delivery, even on orders under $50, which is an increase from 68% the previous year. Additionally, extended delivery times can lead to customer dissatisfaction and damage the reputation of your brand. In-house fulfillment often struggles to offer competitive shipping rates and fast deliveries, particularly as your business expands.

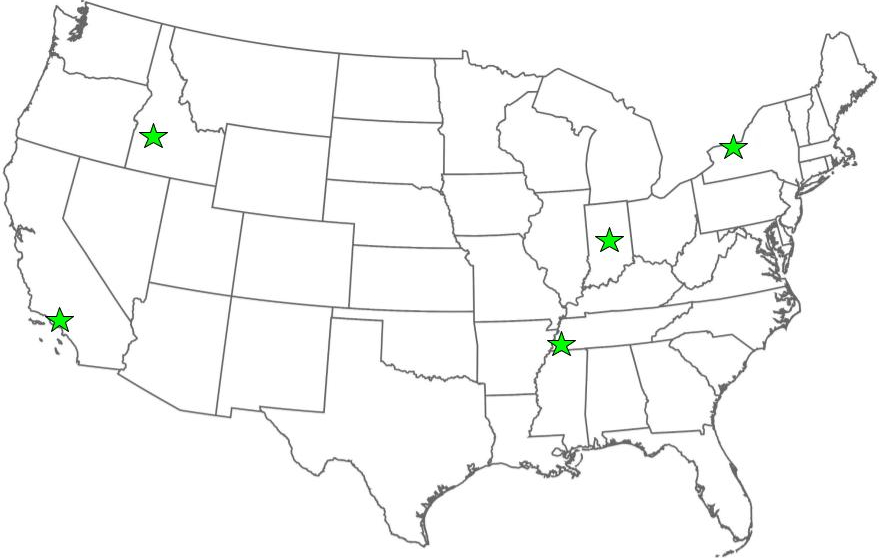

One solution to this problem is outsourcing fulfillment to a third-party logistics (3PL) company. These companies handle large shipping volumes, allowing them to negotiate better rates with carriers and pass those savings on to you. Moreover, many 3PLs have multiple distribution centers, enabling you to store your products closer to your customers. This proximity can significantly reduce delivery times, resulting in happier customers and increased repeat business.

KNOWING WHEN TO OUTSOURCE

Consider outsourcing your fulfillment operations to a specialized 3PL provider if any of these scenarios sound familiar. Wolff/SMG Fulfillment is dedicated to simplifying your fulfillment process, allowing you to focus on your core business.

Opting for a reputable 3PL partner like Wolff/SMG Fulfillment not only enhances operational efficiency but also enables you to leverage their expertise and infrastructure. Wolff/SMG’s omnichannel fulfillment capabilities ensure a seamless experience for your customers, regardless of their preferred shopping platform. With our focus on B2B and e-commerce, we understand the unique demands of these sectors and cater to them accordingly.

Outsourcing fulfillment does not equate to relinquishing control over your business. Instead, it is a strategic allocation of resources, allowing you to concentrate on your strengths: creating exceptional products and nurturing customer relationships.

Remember, transitioning from in-house to outsourced fulfillment is not simply a change of address for your products. It is a well-thought-out decision that can positively impact your business. By partnering with Wolff/SMG Fulfillment, you are selecting a seamless and efficient solution that grows alongside your business, ensuring you are always equipped to meet your customers’ needs and expectations.

The timing for the shift to outsourced fulfillment varies for each business. However, if you are facing the aforementioned challenges, it may be time to make the transition. Contact Wolff/SMG Fulfillment today to discover how they can streamline your order fulfillment, manage your inventory, and facilitate the smooth scaling of your business.